Sesebelisoa sa motlakase sa SMT

Melemo:

1. Tšebeliso ea sephutheloana sa "Carrier tape" bakeng sa SMT

2. High rated current, Low DCR.

3. E loketse bakeng sa reflow SMT Craft soldering.

4. Haha ho latela melao ea RoHS 'me u etelle pele mahala

5. High saturation konokono lintho tse bonahalang le tse nyenyane boholo

6. Phallo ea metsi ho fihla ho 14 A

7.CD31/CD32/CD42/CD43/CD52/CD53/CD54/CD73/CD75/CD105/CD105 e teng bakeng sa kgetho ya hao.

8. Sephutheloana: Sephutheloana sa Tape & Reel.

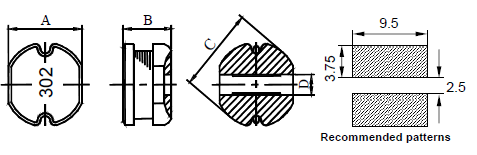

Boholo le boholo:

| A | B | C | D |

| 9.0±0.3 | 6.4±0.3 | Φ10.0±0.3 | 3.0±0.3 |

Lintho tsa motlakase:

| ITEM | SPEC. | MAMELLO | TESI MAKOANE | MOSEBETSI TEKO |

| TS'ELISO | 3.0mH | ±10% | 100kHz/0.25V | HP-4284A |

| DCR | 7.2Ω | Max. | ka 25°C | CH-502A |

| IDC | 0.32A | L0A*90% Mim. | 10kHz/0.25V | CD106S+CD1320 |

Lisebelisoa:

1. Ho fetola lilaoli tse nang le li-voltage tse tlase tsa ts'ebetso (likarete tsa litšoantšo, likarete tsa PC tse kentsoeng, liboto tse kholo)

2.Integrated DC/DC converter

3.Lighting LED, thepa ea puisano e nkehang,

4. Lekola, Khamera e nkehang, Khokahano ea mehala, lihlahisoa tsa dijithale

U ka khetha inductor e nepahetseng ea chip joang bakeng sa ts'ebetso ea chip ea SMT?

1. Kakaretso ea bophara ba chip inductor e lokela ho ba tlase ho bophara ba kakaretso ea inductor ho qoba lisebelisoa tse feteletseng tsa soldering hore li se ke tsa baka khatello ea maikutlo e feteletseng ho fetola boleng ba inductor ha metsi a pholile.

2. Ho nepahala ha li-inductors tsa chip tse fumanehang 'marakeng oa thekiso hangata ke ± 10%. Haeba ho nepahala ho feta ±5%, o tlameha ho odara pele ho nako.

3. Li-inductors tse ling li ka chesetsoa ka ontong ea reflow le wave soldering, empa ho boetse ho na le li-inductors tse ke keng tsa chesoa ka wave soldering.

4. Ha o ntse o fetisoa, ho ke ke ha khoneha ho nkela sebaka sa motlakase sebaka ka mochine oa chip feela ka palo ea inductor. E le ho netefatsa litšobotsi tsa ts'ebetso, ho boetse hoa hlokahala ho utloisisa mefuta ea maqhubu a ts'ebetso ea li-inductors tsa chip.

5. Sebopeho sa ponahalo le motheo oa litlhaloso tsa li-inductors tsa chip li tšoana, 'me sebopeho sa ponahalo ha se na letšoao la bohlokoa. Ha li-soldering kapa li-patches tse entsoeng ka letsoho, u tlameha ho ba hlokolosi haholo 'me u se ke ua etsa liphoso kapa ua nka likarolo tse fosahetseng.

6. Mothating ona, ho na le li-inductors tse tharo tse tloaelehileng: mofuta oa pele, li-inductors tse phahameng-frequency bakeng sa ho futhumatsa microwave. E sebetsa ho li-frequency range applications ho pota 1GHz. Mofuta oa bobeli ke li-inductors tsa maqhubu a phahameng haholo. E loketse letoto la resonance control circuit le frequency selective power circuit. Mofuta oa boraro ke li-inductors tse sebetsang. Ka kakaretso e sebetsa ho lipotoloho tsa matla tsa mashome a megahertz.

7. Lihlahisoa tse fapaneng li sebelisa li-diameter tse fapaneng tsa li-coil tsa makenete. Esita le haeba palo e lekanang ea inductor e sebelisoa, tekanyo ea khanyetso e bontšitsoeng ha e tšoane. Ka loop ea taolo ea maqhubu a phahameng, tekanyo ea ho hanyetsa e kotsi haholo ho boleng ba Q, kahoo e ele hloko ha u etsa moralo.

8. E lumelloa ho ba palo ea index ea chip inductance ho ea ka palo e kholoanyane ea hona joale. Ha potoloho ea phepelo ea motlakase e tlameha ho ikarabella bakeng sa palo e kholo ea hona joale, boleng bona ba index ea capacitor bo tlameha ho nahanoa.

9. Ha li-inductors tsa matla li sebelisoa ho li-converter tsa DC / DC, boholo ba li-inductors tsa bona hang-hang bo beha kotsing boikutlo ba ho sebetsa ba potoloho ea matla. Ho ea ka boemo ba sebele, mokhoa oa ho lokisa coil ea makenete hangata o ka sebelisoa ho fetola li-inductors ho finyella liphello tse sebetsang.

10. Li-inductors tsa maqeba a marang-rang li tloaelehile ho lisebelisoa tsa puisano tse sebetsang sebakeng sa maqhubu a 150 ~ 900MHz. Potolohong ea motlakase e potolohang 1GHz, ho tlameha ho sebelisoa li-inductors tsa microwave tse futhumatsang maqhubu a phahameng. Ha moreki a sebelisa mofuta oa smt patch, ehlile, e boletsoe ka likarolo tse fapaneng. Ke feela mokhatlo oa ts'ebetso o ka tiisang hore e hlile e kopantsoe 'marakeng oa thekiso ka mor'a ho nahana ka melao e feletseng ea bareki.